Chemtrol Industries manufactures the most comprehensive line of Non-metallic Fiberglass Reinforced Thermoset Resins (FRP/GRP) Centrifugal Pumps for handling corrosive fluids having a PH range between 0-14, such as HCL, Dilute H2SO4, NaCl, Sea Water, Caustic, Dyestuff Slurries, Effluents, Nitric Acid, Alum, Saltwater and other complex liquids. Composite Fiberglass Reinforced Plastic (FRP) has substituted other more expensive metals such as high alloys, duplex steel, titanium, etc., in many industrial process equipment, such as Tanks, Reactors, Columns, Pumps, Piping, Duct and Hood systems, due to its excellent corrosion resistance properties. Our ‘Hand Lay-up’ process ensures emulsion of each fibreglass layer into Resin, keeping no room for air to be trapped.

Our Mechanical Seal Pumps have a single composite structure of Threaded Impeller with embedded shaft sleeve. This jointless structure eliminates liquid penetration towards the shaft from the impeller and the impeller nut joints, as well as the impeller and the shaft sleeve joint. We can select the internal as well as external mechanical sleeve having different stationary and rotating material depending on the liquid to be handled.

CHEMTROL INDUSTRIES’ has the honor of being the pioneer for Manufacturer of FRP Molded (Fiber Glass Reinforce with Vinyl Ester Resin) Centrifugal Chemical Process Pumps in India and has been accredited.

Chemtrol Pumps has more than 6000 installations over the years.

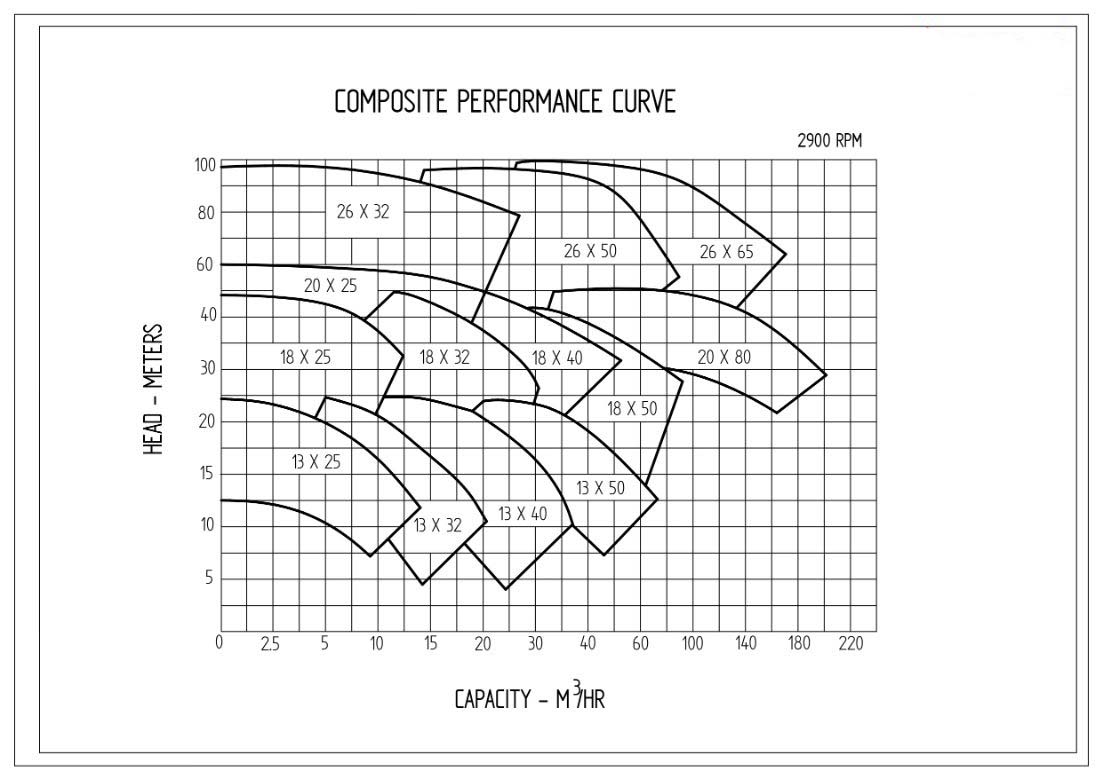

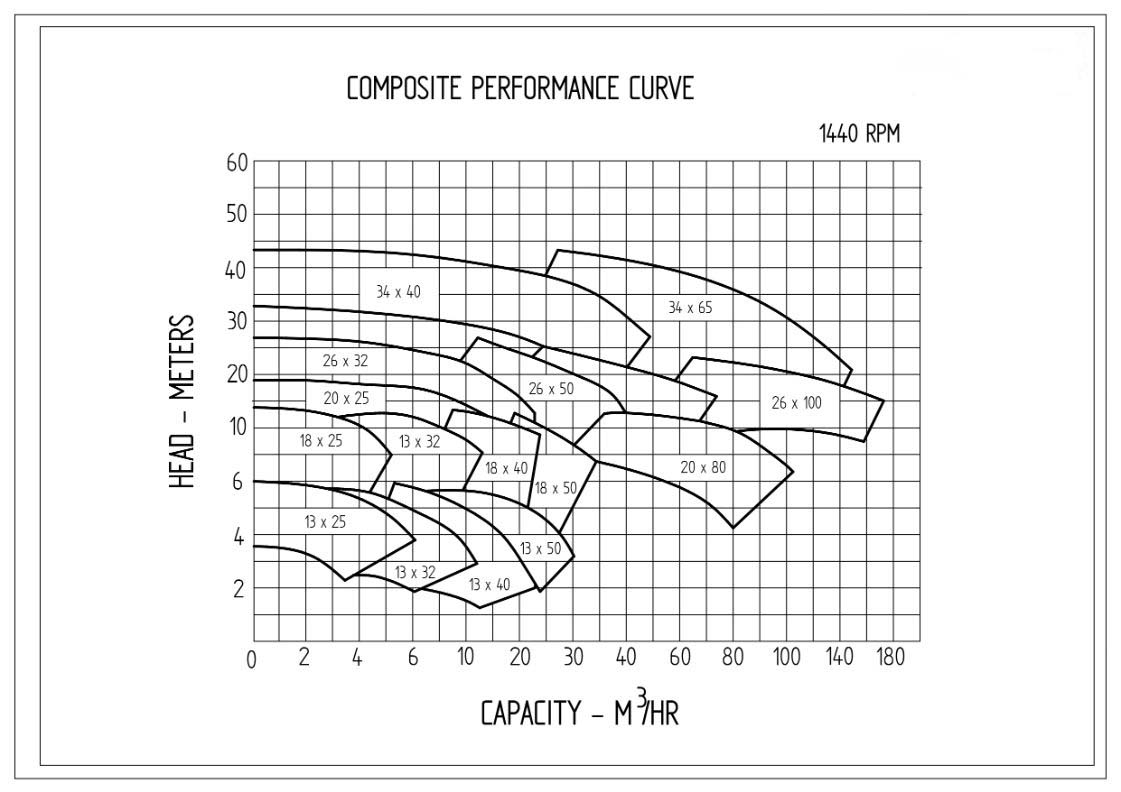

CHEMTROL FRP Pump series is India’s FIRST Non-Metallic Composite structure Pump design. FRP Construction is substitute to Duplex Steel, High alloy steel, lined and plastic construction pumps. The standard lower RPM advantage may not

be applicable in our anticorrosive pumps, since the damage is usually due to corrosion and not due to normal wear and tear. Hence the FRP pumps on 2900 RPM are more economical as compared to other types at 1440 RPM. Chemtrol pumps

are specifically designed with all the wetted components viz. Casing, Casing Back cover, Impeller, Impeller Nut and Gland Pusher are made from Single Composite structure of Fiberglass Reinforce with Vinyl Easter Resin which ensure

excellent resistance to corrosion and abrasion, superior impact resistance and mechanical strength. Unlike Thermoplastics, It is established that FRP/GRP is a thermosetting material, having better physical & mechanical properties

like the resistance to corrosion, abrasion, temperature, mechanical strength as compared to thermoplastics.

Moreover, FRP components at times can be repaired unlike any other plastics. In chemtrol FRP pumps i.e Fiberglass

Reinforced Polyester Resin, Polyester resin being used is of Vinyl Easter grade and these resins set permanently. As per the customer demand and application we also manufacture these pumps with super vinyl ester resins, which in

turns increases the strength as well as durability of the FRP molded components in the pumps. We therefore reckon that FRP could be the best possible solution to corrosion resistant / reliable material amongst all plastics. For

your perusal we are enclosing herewith “Physical & Mechanical Properties “of FRP are listed here. While Chemtrol pumps are ergonomically designed, especially the casing incorporated in our FRP pump is a Single Volute type with

contoured discharge, the same is equivalent to the the standard available for horizontal end suction centrifugal metallic chemical process pumps.

This particular design is not usually available in other non-metallic plastic

pumps available in India. This design enhances the discharge efficiency of the pumps and compared to other non metallic pumps. The constructional features of our FRP pumps can be easily compared with various Indian as well as International

standard viz. IS 1520 DIN 24256 and API 610 etc. Equipped with semi-open impeller to eliminate choking problems and the back-pull-out design to facilitate easy maintenance of the standard gland packed pumps. While additionally

for the mechanical seal arrangement a unique impeller has been designed, which consists of single composite, jointless FRP component, consisting Impeller, Impeller Nut and Shaft sleeve. We are working on ANSI series pumps and will

be available shortly.

This particular feature renders absolutely leak-proof arrangement thereby preventing liquid penetration to the shaft from the joints Impeller, Impeller and the shaft Sleeve. Hence this eliminates

use of costly Duplex shafts. Moreover, gland plate for holding mechanical seal is also offered in FRP construction. Easy external adjustment of impeller, providing compensation for wear and ensuring consistent performance. Low

weight to dimension ratio ensuring smooth and vibration free performance even in large sizes run at high speeds. Maximum parts interchangeability reducing spares inventory. All exposed components are coated with anti-corrosive

protective epoxy paint to withstand the corrosive-working atmosphere. Heavy-duty bearings provide for smooth and cool operation even at higher speeds. The oil- sump in bearing housing is larger and stores more quantity of oil for

efficient lubrication and cooling.

| Specific Gravity : | 1.6 To 1.8 |

| Thermal Conductivity B.t.u./ | 1.2 To 1.6 (In./Sq.ft/0F) |

| Coefficient of Thermal Expiation – 0Fx10-6 | 12 To 20 |

| Flammability | Self – Ext. |

| Tensile Strength - 103 PSI | 09 to 20 |

| Elongation (in 2 in) | NIL |

| Hardness (BARCAL) | 35 |

| Flexural Strength - 103 PSI | 14 |

| Compressive Strength - 103 PSI | 18 TO 25 |

| Max. Recommended Service Temp. - 0°C | UPTO 100 |

| Heat Distotation Temp. - 0°C | 125 |

| Colour & Appearance | Light Yellow colour Liquid |

| Viscosity @ 20°C (By Brook Field Viscosity) | 1.2 To 1.6 (In./Sq.ft/0F) |

| Styrene content by Wt. % | 45 – 47 |

| Specific Gravity at 25°C | less than 1.06 |

| Vinyl Ester resins gm | 100 |

| Cobalt Octate 3% si In | 1.5 ml |

| MEKP so In. | 1.5 ml |

| Styrene content by Wt. % | 25 – 47 |

| Gel Time (in.min.) | 25 |

| Heat Distortion Temp. | Max 99°C |

For Maintenance of FRP composite by process of:

Conceptual approach to inventory control through maximum dimensional interchangeability has achieved optimum design standardization leading to a large number of permutations between various pump models and motor frames on a limited number of base frames, power and assemblies.

Our spares come with an interchangeabilitycertificate, so you can rest assured that spare parts are easy to replace.

_page-0001.jpg)